In this article you will find instructions and tips about setting the floating vibrato unit (also inappropriately called tremolo) of an electric guitar, with special regard to the iconic kind often used on super-strat style instruments. Whether original or licensed, I am going to deal with the Floyd Rose vibrato! At the end of the article I am going to mention Kahler vibratos too.

This is part of the general setup

of the guitar, that involves topics covered on the Soundsation blog as intonation, pickup and action adjustments.

Before continuing you should have:

All that verified, we can talk about

how to self-adjust a vibrato bridge with two studs and a locking nut.

Please remember that the setting of

a Fender vintage style six screw vibrato is debated in the Soundsation blog

article “The setup of your guitar (PT. 7) –Setting a vintage style vibrato”. The setting of floating bridges with two studs without a

locking nut, as the Fender® American Standard and the Wilkinson® VS100N, is dealt with in the article “The setup of your guitar (PT. 8) -Setting a floating style vibrato or tremolo” and is largely valid for double locking bridges.

In this article I am going to talk about the latter ones, that is floating and locking vibratos with two studs, a locking nut and fine-tuners

for tuning refinement.

Double

locking floating bridges: the Floyd Rose

Here is the king of floating

vibrato bridges: the Floyd Rose. This revolutionary bridge bears the

name of its creator, goldsmith and guitarist Floyd D. Rose, who, after

practising steel working, began to offer it as a craftsman in 1976. Part of

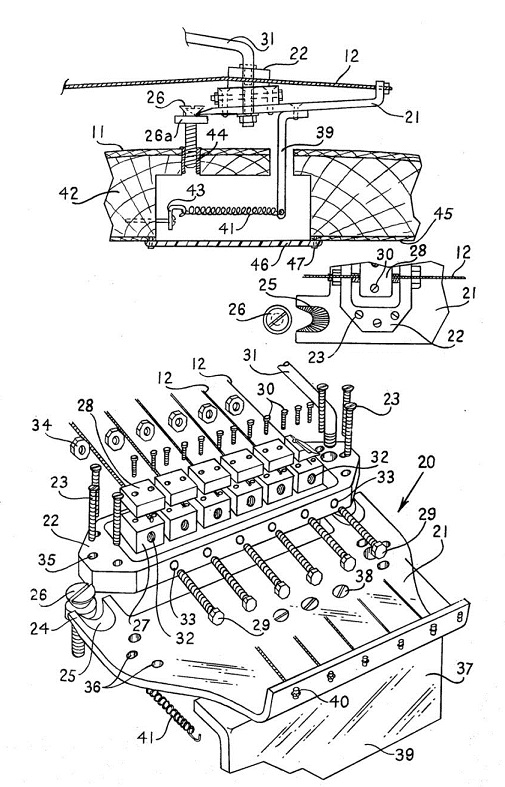

1979 patent is showed in the drawing below.

Among the early purchasers of the FRT-1 model (without fine-tuners) there was Randy Hansen, at the time certainly the greatest emulator of Jimi Hendrix. He bought the second made piece and helped make it known on the music scene.

Neal Schon (Santana, Journey), Brad Gillis (Night Ranger) and Eddie Van Halen followed. Floyd Rose managed to build about fifty vibratos in his Seattle based workshop, before he was submerged by requests and decided to outsource production to the Japanese company Fernandes in 1981. In 1982 Van Halen had six fine tuners implemented on his bridge, a solution that was adopted later by Fernandes on the FRT-4 model.

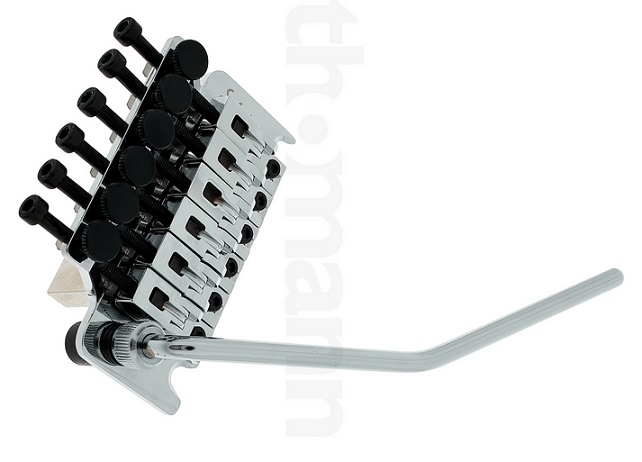

In 1983 Japanese production was supported by the German company Schaller (FRT-3, still without fine-tuners) and a trade deal was made with US Kramer Guitars. After some vicissitudes and license grants, today manufacturing still goes on in Germany under the Floyd Rose Original brand. Used materials are steel for saddles and nickel-plated brass for sustain blocks, though the early models were completely made of steel. Schaller offers steel-made Lockmeister (in the photo) and Vintage models under its own brand.

Over the years Ibanez has been proposing greatly successful bridges made by Gotoh under the Floyd Rose license: from the first 1986 Edge to the well-known Lo-Pro Edge, a low-profile model such as the Floyd Rose Pro.

Besides the German Floyd Rose Original bridges, there are also the Korean built Floyd Rose Special ones, featuring zinc alloy sustain blocks and saddles.

Double

locking bridge breakthroughs

Double locking tremolo main idea is simple: locking the

strings at the saddles and at the nut, thus making impossible the

detuning due to the arm use. This allows vibrato excesses that were

unimaginable before, making the strings literally drop on pickups (dive

bombing) and having them back perfectly in tune as soon as the arm

is released!

To lock strings before the

headstock, Floyd Rose designed the locking nut, a metal attachment that

replaces common nuts and is fixed to the guitar neck with two bolts. The

strings rest on the locking nut and are fastened by clamps and/or Allen screws.

On the opposite side, the strings are inserted into the saddle slots without passing through the sustain block and are also fastened by Allen screws. The first portion of the string, the one that has a dot, must be cut off in order to make it access the saddle. On the market you can buy strings with no dots that were designed to be used with double locking bridges. Some musicians are used to insert string dot sides from tuners, using the free head for saddle insertion.

A

fundamental breakthrough of the Floyd Rose was the change

from traditional Fender style six screws to two solid studs on which the

knife edge of the bridge rests and swings.

The use of two studs only, adopted later by several designers for their own vibratos, was very important because it promoted the development of new guitar sounds and expressive techniques. I am sure that Jimi Hendrix would not have hesitated to try a Floyd Rose on his Stratocaster.

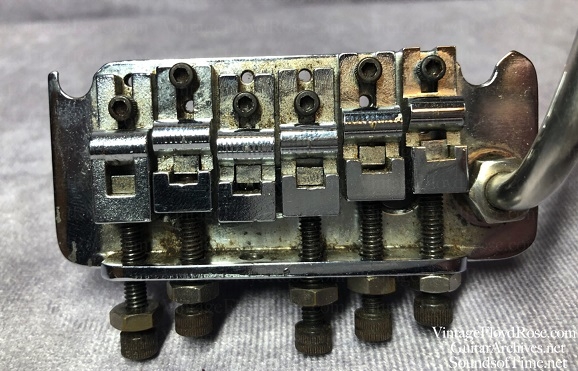

Early

Floyd Roses

First years Floyd Roses did not feature fine-tuners, thus strings had to be tuned with experience and patience slightly flat, thus voiding the pitch increase due to fastening the locking nut. This considerable minus was solved with little fine-tuning knobs, though there will always be someone who argues that vibratos without fine-tuners “sound better” because they have fewer parts.

Early Floyd Roses, starting from Eddie Van Halen's one, were mounted flush

on the guitar top. In fact the original idea was to avoid tuning loss under

vibrato use. In 1987 the Ibanez JEM guitar was introduced, featuring a special

dig that Steve Vai wanted behind its Floyd Rose inspired bridge. This

routing allowed a better use of the arm in order to make both ascending and

descending movements.

This is the ultimate double locking vibrato we find today in 90% of cases, featuring a recessed routing behind and/or around the bridge, fine-tuners and a locking nut. So we are now enjoying the highest, ready from factory evolution of a system that in the beginning needed a professional installation by skilled luthiers and irreversibly modified instruments.

Double locking and materials

Almost all guitar and hardware

manufacturers have the described double locking vibratos in their lists,

eventually matched by locking tuners (Schaller, Sperzel, Gotoh) that have strings tightened in their holes (in my

opinion they are redundant because of a locking nut presence).

Materials floating bridges are made of are

fundamental for their mechanic and sound quality. Certainly, steel is

preferable at least for saddles, base and studs; it provides strength,

the best vibration transfer speed and a good sustain.

Aluminium, brass and zinc alloy are

also used to make sustain blocks (also called tremolo blocks).

Stud and knife edge processing quality are very important for bridge

durability and operation smoothness.

Double locking bridge pluses

- Unrivalled

action fluidity, intonation range and tuning holding

- Best

models feature remarkable sound consistency and long lasting tuning

and pitch, virtually making setup checking necessary only at string

replacement.

Double locking bridge minuses

- The overall sound of the instrument

is very different from a vintage style guitar one, with a decisive contribution of the bridge.

However, double locking bridges are usually featured on guitars with powerful

modern pickups, often designed for heavy rock and similar genres, so, in my opinion, there is no

problem

- You have to change strings one at a

time to avoid that a sudden tension loss makes the bridge

lose its grip on the studs and “collapse” on the guitar top, while the claw

bracket unhooks the springs. When fretboard cleaning or polishing is needed, and you have to clear

the instrument from all the strings, you should put a wood, plastic or

hard rubber wedge under the rear side of the bridge to avoid troubles.

Take

care of...

Always remember that the more the

string to saddle contact point gets up, the flatter the general pitch of the instrument will get (you are

extending the scale).

It is also important to know that

when you are planning to replace the bridge with a more efficient one, measures

must be the same or compatible, particularly the saddle lengths, because it

is possible to risk changing the instrument scale and get a complete

intonation loss of the fretboard. When in doubt, always turn to a luthier!

Height

and radius settings

First of all loosen the locking nut

and tune the guitar. To adjust a double locking bridge you can follow what has

been said about non-locking floating bridges. The

procedure is even simpler because you have to operate only on the studs,

lacking the saddle individual height settings.

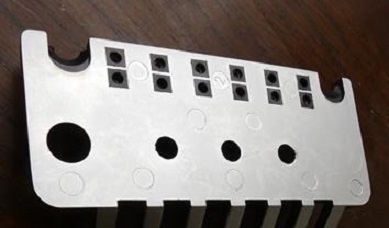

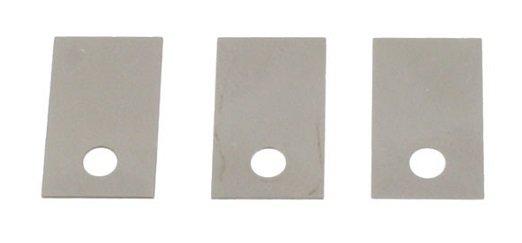

In fact double-locking bridge builders give fixed preset heights for plain/wound E, D/G and A/B strings that are suitable for the most common super-strat radiuses. Sometimes these saddles can be replaced with different measure ones. If you are a perfectionist and you want a custom radius, turn to a luthier, who will use metal shims (in the photo) or a milling machine to raise or lower the saddles. Obviously, the second operation is “destructive”.

The bridge height and position on the guitar top are firstly adjusted acting on the springs, usually two or even three if you use a string set with a .008 or .009 first string; three springs for a .010-.046 set. You have to operate on the claw screws that attach the springs to the guitar body, as described in the PT.7 about Setup of our blog. Then you will have to lower the studs as much as possible till you get an acceptable action.

Intonation

setting

As regards intonation, you

have to loosen the saddle fastening screws to make them free to move forward

and backward. Then you will have to operate on the rear Allen screws as

described in the PT.7 about Setup of the Soundsation blog. The problem

is the forward pull that a loose saddle suffers from the string. Hence

it is necessary to release significantly the string, then tune it again,

repeating these operations several times until the desired result is reached.

The market offers useful devices

that can be attached to saddles and facilitate shifting, as the Floyd Rose

The Key or the Ibanez EJK1000 (in the picture).

Alternatively, you can lift the rear side of the bridge and reduce the string pull with a block of wood or other material that will not harm the top finish. Somebody prefers to use a post-it pad detached to size. You have to remove the wedge every time you check the adjustment result, then put it back in position for the next action. You can make yourself this object or look for devices as the ShredNeck TremBlock from luthier suppliers. The important thing is not to risk to damage the guitar paint.

As for all floating bridges, except

perhaps G&Ls, you have to replace strings one at a time in order to

avoid the vibrato system collapses under the spring traction. If you want to

change all the strings at the same time, you should use a bridge raising

device.

At the end of all adjustments you

can tighten the locking nut. But, before doing this, you have to tune the

strings, have all the fine-tuning knobs halfway or, better, a little higher,

that is barely flat. This way, after locking the nut, you will have enough room

for fine calibration in both senses.

Useful

gear

I point out devices as the

Tremolo Buddy by Floyd Rose, that helps to fulfil all setup and string

replacement operations.

Dampers as the Trem-Endus Tremolo

Stabilizer (in the picture) or the Super-Vee Mag-Lok help the vibrato

stabilisation. Similarly to the Hipshot Tremsetter, they also control pitch

drops of open strings during bendings.

Kahler

bridges

Floyd Rose's less fortunate relative

mainly came by a millionaire lawsuit sued by the first locking vibrato creator

against Gary Kahler, guitar player, metalwork businessman (Kahler

Systems International), Fender and DiMarzio hardware contractor (American

Precision Metal Works, Brass Factory). In fact, early Kahler models of the '80s

had common points with Floyd Roses: they were two stud mounted, double locking

and floating! The suit led to the indication “under license from Floyd Rose”

on Kahler vibratos (a Steeler in the photo).

The next and most accomplished Kahler bridge (mod. 2300 for Stratocaster) was essentially different from the Floyd Rose.

The new Kahler bridge was flat mounted over or into the guitar top (recessed routing) with two short springs placed in a little dig under the bridge, a rotating cam with two ball bearings, six rollers as saddles and a locking nut (today no more supplied by Kahler). It is not a strictly double locking bridge and the Strat rear rout is not even used, so much so that this was the choice vibrato for Gibson style solid-bodies (mod. 2200 attaches directly to the tailpiece studs).

In the '90s Gary Kahler went out of the music business and devoted himself to other, until he came back in 2004 manufacturing sophisticated guitar and bass vibrato as the Multi-Scale.

Kahler 2200/2300 adjustment

possibilities are many and facilitated by the fixed flush fitting on the body.

Saddles can move forward and backward, upward and downward, to the left and to

the right; so you can set heights, radius, intonation and string spacing

working only on the saddles. Spring tension is also adjustable. Kahler bridges

feature fine-tuners and arms that can be installed right-handed or left-handed

on the same unit.

This is perhaps the most sound

influential guitar bridge, but it is refined, solid

(steel/brass) and very smooth in using. It provides a good sustain

and is ideal for... very heavy hand guitar players!

Fabrizio

Dadò

References

D.Erlewine, Guitar Player Repair Guide - Miller

Freeman Books, 1990.